Sakura Services

Sakura France Service supply you professional machine made in Japan,

strong, compact, and with a high productivity

Why go for automatic sushi production?

Rinsing

Rice has to be rinsed to extract starch and clean away any dust residues. The rice must be rinsed between three and five times until the cooking water is clear.

Cooking

(Based on a rice cooker with capacity 4 kg of cooked rice) A five to ten-minute cool-down period must be added to the cooking time before mixing with vinegar.

Mixing

Vinegar must be mixed with the rice making sure it is evenly dispersed. The rice must then be cooled to around 20°/ 25°, so that surplus vinegar is expelled.

Measuring

The quantity of rice must be measured so that the correct amounts of water (for cooking) and vinegar (for the final mix) are used. For optimum effectiveness, use 20% less than the capacity of the automatic cooker.

PREPARING THE SUSHI

RICE

Rice is the basic ingredient of sushi, so it must be perfect!

Before cooking and shaping, it is essential to wash the rice in order to remove as much as possible of the starch present on the surface of the rice grains.

This is a very painstaking and time-consuming stage when done by hand and so we offer two automatic washers. Just pour in the water and rice and press the button.

Example based on 6Kg of rice

manual method

3H15

automatic method

1H50

MEASURING

- Measuring has to be done manually

15 minutes

- The washer automatically adjusts the volume of water for the quantity of rice

0 minutes

RINSING

- The rice has to be washed several times to remove as much of the bran as possible

45 minutes

- During the cycle, the bran will be removed and the rice stirred rapidly and evenly

10 minutes

COOKING

- Exact measurements and constant supervision are required to achieve the perfect rice

90 minutes

- The rice does not stick and you no longer have to watch it constantly

90 minutes

MIXING

- Great care must be taken to achieve an even mix. Then it must be left to cool

45 minutes

TOTAL : 240 minutes (4h)

- The mix is even and at the right temperature, before cooling

10 minutes

TOTAL : 55 minutes

When making the rice, it’s only the cooking time that cannot be reduced.

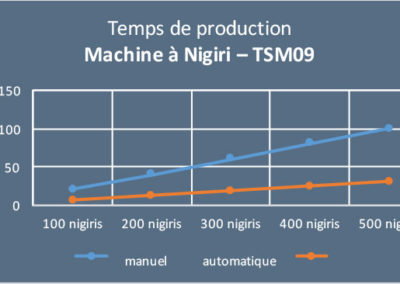

As shown in the diagram below, in our example a time-saving of more than one hour can be achieved in the rice preparation cycle.

Added to that is the fact you can start the machines and then get on with other, unlike with the manual method.

Saving time in the Sushi production process

Cost savings

Using rice and sushi making equipment will save you time, meaning that you can employ fewer staff and so reduce your wage bill.

This equipment will allow you to rationalise your production and accurately calculate the price for your finished products.

Comparison between a Sushi Chef

&

a Complete Machine Pack

SUSHI CHEF

- Difficult to make good quality sushi

- Variable weights and volumes of sushi

- Non-uniform sushi

- High wastage of ingredients

- Need for training

- Takes time and costs more

- Can leave your employment at any time